Since the beginning of its business, our company is engaged in the manufacture of suspension components for the drywall systems and engineering activities. We're constantly updating and improving our manufacturing activities. That's why we use professional software programs and modern equipment, we can meet your requirements. We use both, traditional machine tools and CNC (wire EDM machines) and CNC milling machines. We concentrate on the production of stamping, cutting, bending and combined tools, simple parts, complex products and molds.

Since the beginning of its business, our company is engaged in the manufacture of suspension components for the drywall systems and engineering activities. We're constantly updating and improving our manufacturing activities. That's why we use professional software programs and modern equipment, we can meet your requirements. We use both, traditional machine tools and CNC (wire EDM machines) and CNC milling machines. We concentrate on the production of stamping, cutting, bending and combined tools, simple parts, complex products and molds.

If you do not have the possibility to operate yourself on our manufactured tool, we are able to begin production on our presses. Our press machines are equipped by electronic feeders and self-uncoiling devices, to produce from steel coils. We also offer the option to produce from steel strips, according to the type of instrument.

We provide:

CNC Milling / CNC Turning / Electro Discharge Machining (EDM) / 3D laser cutting and welding / 3D measurement / Grinding 300 x 1000 mm / 200 x 600 mm / turning / milling / drilling / Cold stamping

3D laser cutting

Cutting of material by laser beam is nowadays the most common industrial operations. Wide application is also in the processing of metal materials. The advantage of laser cutting is especially the speed, thin kerf, high precision and non-contact material processing. Currently, the laser cutting is much more efficient process comparing the classic conventional techniques.

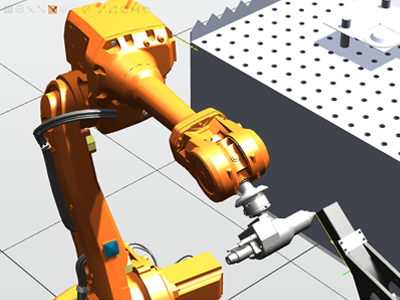

Robot ABB / IRB 4600 / Laser device Fiber 1000W

● Cutting up to thickness 8 mm of steel

● Process gases: oxygen and nitrogen

● Welding of steel and aluminum

● Movement of the robot in 6 axes

The advantage of this 3D laser is the option of machining parts (tubes, hollow, sheet metal, etc. ...) after their forming (bending) and the possibility of working on a static, positioning 360° table and a rotator, where the robot operates on one side and the operator may load the parts on the other side. We use software RobotStudio ABB

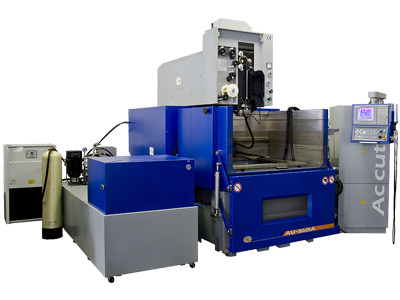

Electro Discharge Machining

This EDM methods consists of taking material by series of discharge (sparks), which randomly occur between the conductive workpiece and the electrode as the tool. For cutting the inner holes of the material must be pre-drilled either conventionally before quenching, or using excavating machine after quenching. By EDM can be machined very fine and complex shapes even to very hard materials such as hardened steel, titanium alloys, etc. Thus for example, radically changed technology of producing instruments, which had previously tempered after machining. The spark machining make the shapes after quenching, so that no deformation danger.

Electro-discharge machining can achieve high accuracy and surface quality similar as grinding.

3 machines capable of machining

● X 360 Y 250 Z 200 mm

● X 560 Y 360 Z 300 mm

● X 800 Y 600 Z 600 mm

We have also the NC hole starter with a diameter of 3 mm.

Table dimensions: 200 X 300 Y 300 Z

CNC milling

Milling is a mechanical machining of metals by multi-blade instrument, wherein the main movement (rotation) performs the tool and side movement (infeed) the workpiece. Classically runs in three axes, in more than three axes operate multi-axis machining centers. Milling is divided into conventional, when the tool is rotated in the direction of the table with a workpiece and climb when it is reversed. As in all sectors, also in the area of machining always leads to innovation, both in terms of hardware (machinery and tools) and in software (CAM systems) and to increase productivity and the ability to compete is necessary to watch these developments.

We produce for Automotive. The parts are made on instruments that were produced in our tool-making workshop.

2 machines capable of machining in 3 / 5 axes, in dimensions:

● X 1050 Y 600 Z 600 mm

● X 1600 Y 1000 Z 1000 mm (5-axis center)

Both machines operate with a control system Mitsubishi

Machine software Siemens NX CAM Express

3D measurement

To ensure the objectivity of measurement of spatially complex technical parts and support TPV in determining eligibility processes utilized modern measuring devices. Measurements can be related either to the values prescribed by conventional drawing or to model that has been created and saved in the form of a 3D electronic file. The measuring probe is mounted on a swivel head that is motorized and indexable.

CMM (Coordinate measuring machine): Nikon Altera 10.7.6.

Precise measurement of components, products, workpieces, etc ...

● X 1000 Y 700 Z 600 mm

● Max table load 500 kg

● Control Program: TouchDMIS

Cold stamping

Pressing parts to material thickness of 8 mm. We use cutting, bending and combined tools. Pressing force on the eccentric presses of 10-250 tons.

A total of 38 press machines with option to stamp from coils using electronic (precision) feeders.